The need for reliable electrical infrastructure has grown a lot because of industrial growth and rapid urban development. Stable and efficient power systems are needed by manufacturing plants, commercial complexes, renewable energy projects, and utility companies to keep running. As energy use goes up, so does the need for solutions that make sure safety, performance, and long-term sustainability.

Power outages or voltage fluctuations can cause production delays, damage to equipment, and lost money. Because of this, companies are putting money into strong transformer technologies that provide reliable load management and voltage regulation. Not only do modern electrical systems have to meet current capacity needs, but they also have to be able to grow without needing expensive redesigns.

Tailored Engineering for Applications with High Performance

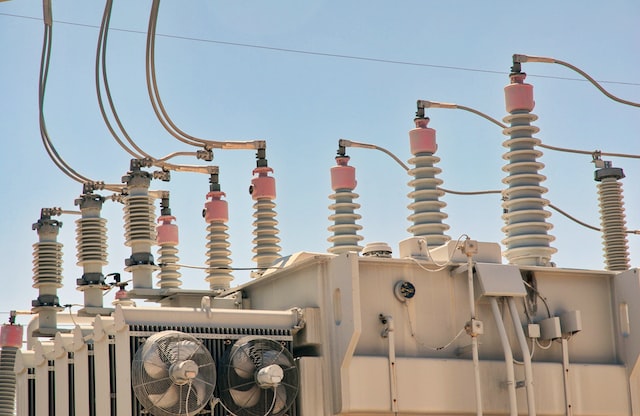

When looking for reliable 3-phase power transformer solutions, businesses often put systems that balance efficiency, durability, and scalability at the top of their list. These transformers are made to handle heavy loads while keeping the voltage output steady across complicated distribution networks.

Customisation is very important for meeting specific operational needs. Transformer design is affected by things like input voltage, output needs, environmental conditions, and load characteristics. Engineered systems make sure that things work at their best under different conditions, whether they are in a factory or part of a renewable energy grid.

Using advanced core materials and precise winding techniques cuts down on energy losses by a lot. Not only does this make operations more efficient, but it also lowers energy costs in the long run. High-efficiency transformer systems help organisations that care about the environment by lowering carbon emissions while still providing reliable power.

Safety, Efficiency, and Following the Rules

Safety and following the rules are still very important for any electrical installation. High-quality transformer systems are built to meet international standards, which makes sure that the insulation stays intact, the system stays stable in heat, and it is protected from faults. Temperature monitoring and overload protection are two examples of protective mechanisms that help keep things from breaking down and last longer.

Energy efficiency standards have also changed, which has forced manufacturers to keep coming up with new ideas. Less no-load and load losses mean big savings over time, especially for big businesses. Companies show that they care about the environment by putting energy-efficient designs first. This not only saves money on operations but also shows that they care about the environment.

Safety is even better when the installation is done correctly and the equipment is maintained on a regular basis. Technicians can spot early signs of wear, overheating, or imbalance during routine inspections. Preventive care keeps service going without interruption and protects important downstream equipment from unexpected problems.

Making Plans for Long-Term Reliability

Companies that think ahead know that transformer systems are investments that will pay off in the long run. Choosing the right configuration from the start cuts down on the need for frequent upgrades or replacements. Businesses can grow without having to change their current infrastructure thanks to scalable designs.

Digital monitoring technologies are now used more often in modern transformer setups. Tracking data in real time gives you information about how the load is behaving, temperature trends, and the health of the system. This predictive method cuts down on downtime and helps facility managers plan for capacity in a smart way.

A strong power infrastructure is the key to success in business. Businesses can keep their operations stable and support growth for a long time by using carefully designed systems that focus on safety and efficiency.

Leave a comment